We are shaping the future of space exploration through revolutionary 3D printing technology. Our mission is to provide the tools and solutions that will allow humanity to expand its reach into the stars.

Revolutionizing space exploration with cutting-edge 3D printing technology.

“Building the tools for tomorrow's discoveries, today”

At NebulaForm, we believe that the next giant leap for humanity isn't just stepping onto new planets—it's building sustainable futures once we get there. We are pioneering advanced space-grade additive manufacturing technology designed specifically for the unique challenges of space exploration, including zero gravity and interplanetary missions.

To revolutionize space exploration and habitation by providing innovative 3D printing solutions that enable the construction of essential infrastructure—from tools to entire habitats—on extraterrestrial surfaces. We aim to expand the possibilities for human and robotic existence beyond Earth, unlocking new potentials, making the impossible possible, and transforming the way we explore and inhabit space.

NebulaForm is committed to accelerating humanity's journey into the cosmos by dramatically shortening the timelines of space manufacturing—from processes that once took years to those achievable in mere days. We achieve this by enabling safe and faster production capabilities that transcend current limitations, providing advanced 3D printing solutions tailored for the unique challenges of space exploration.

Our technology is not just about building structures; it's about building possibilities. By facilitating the expansion of cargo beyond its shipped volume through on-site manufacturing, we play a crucial role in:

We invite you to be part of NebulaForm's pioneering mission—whether as partners, investors, or fellow innovators—to turn the dream of interplanetary living into reality. Together, we can transcend Earth-bound limitations and embrace the boundless opportunities that await us in the cosmos.

Serkan Özkan,

CEO, NebulaForm GmbH

“Shaping the Future of Space Exploration Through Revolutionary 3D Printing Technology”

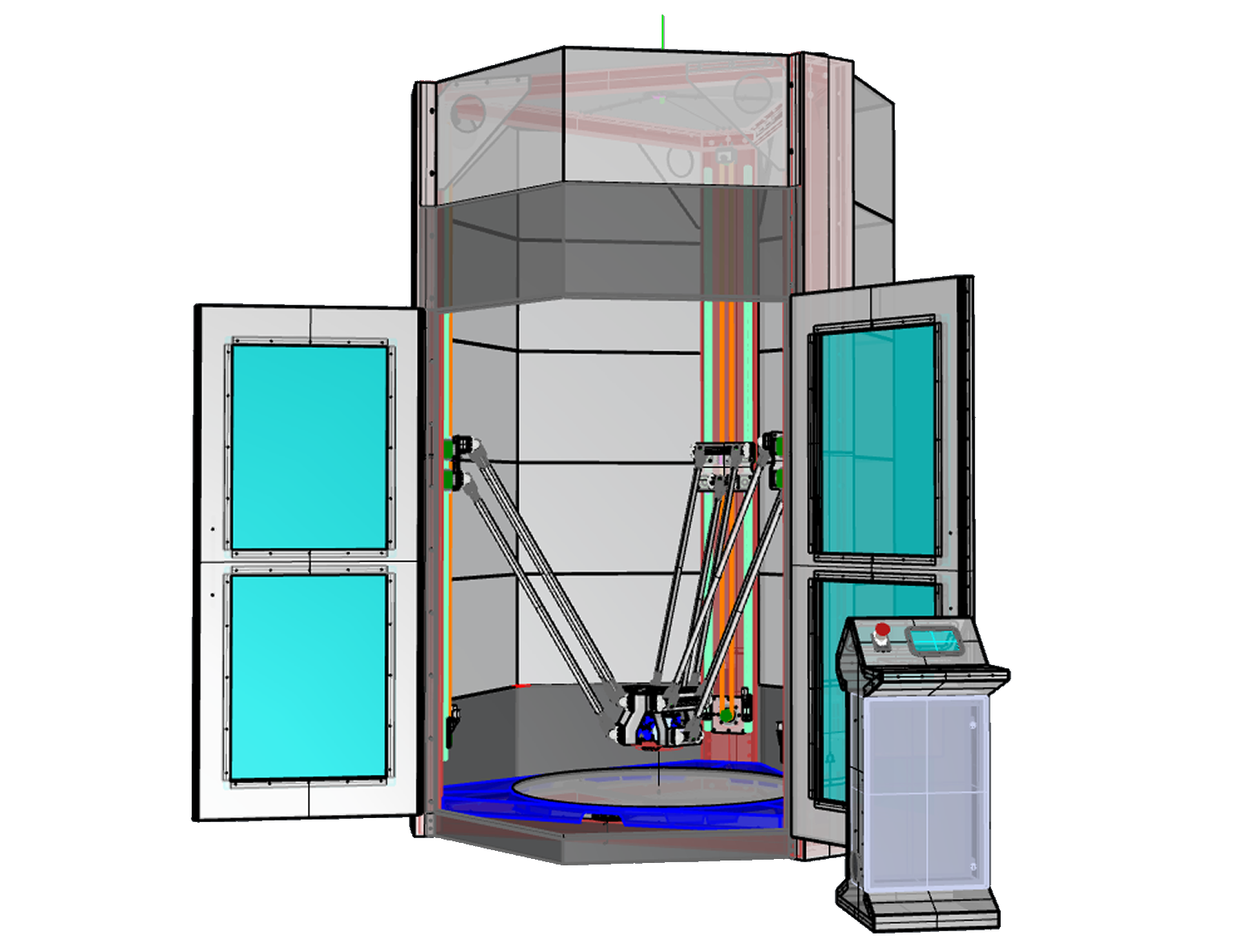

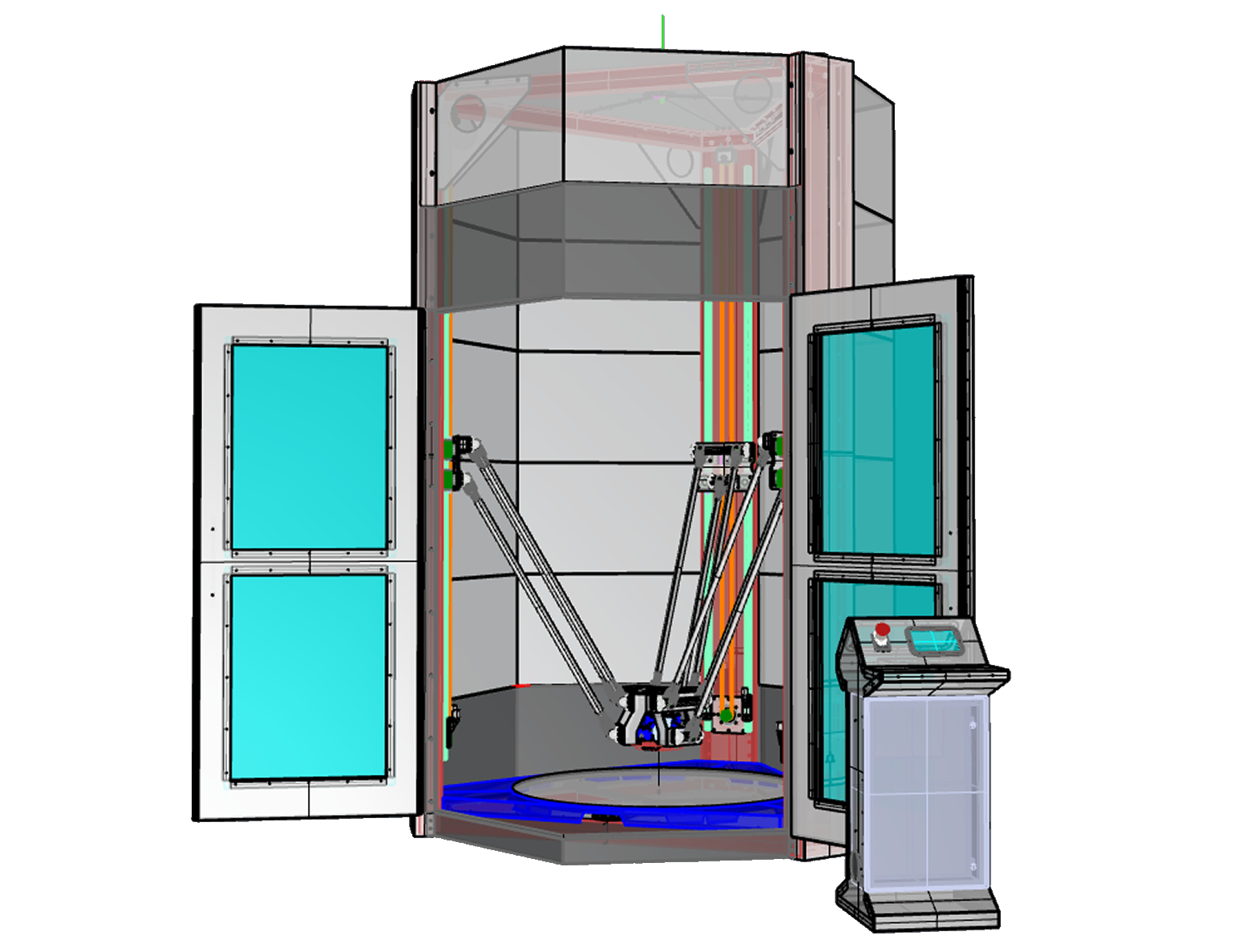

Development of a large-scale industrial delta printer for heavy industries such as aerospace, construction, and energy. HoneyComp3D-Giant optimizes production with advanced materials and faster cycles, designed for space exploration applications.

Read More

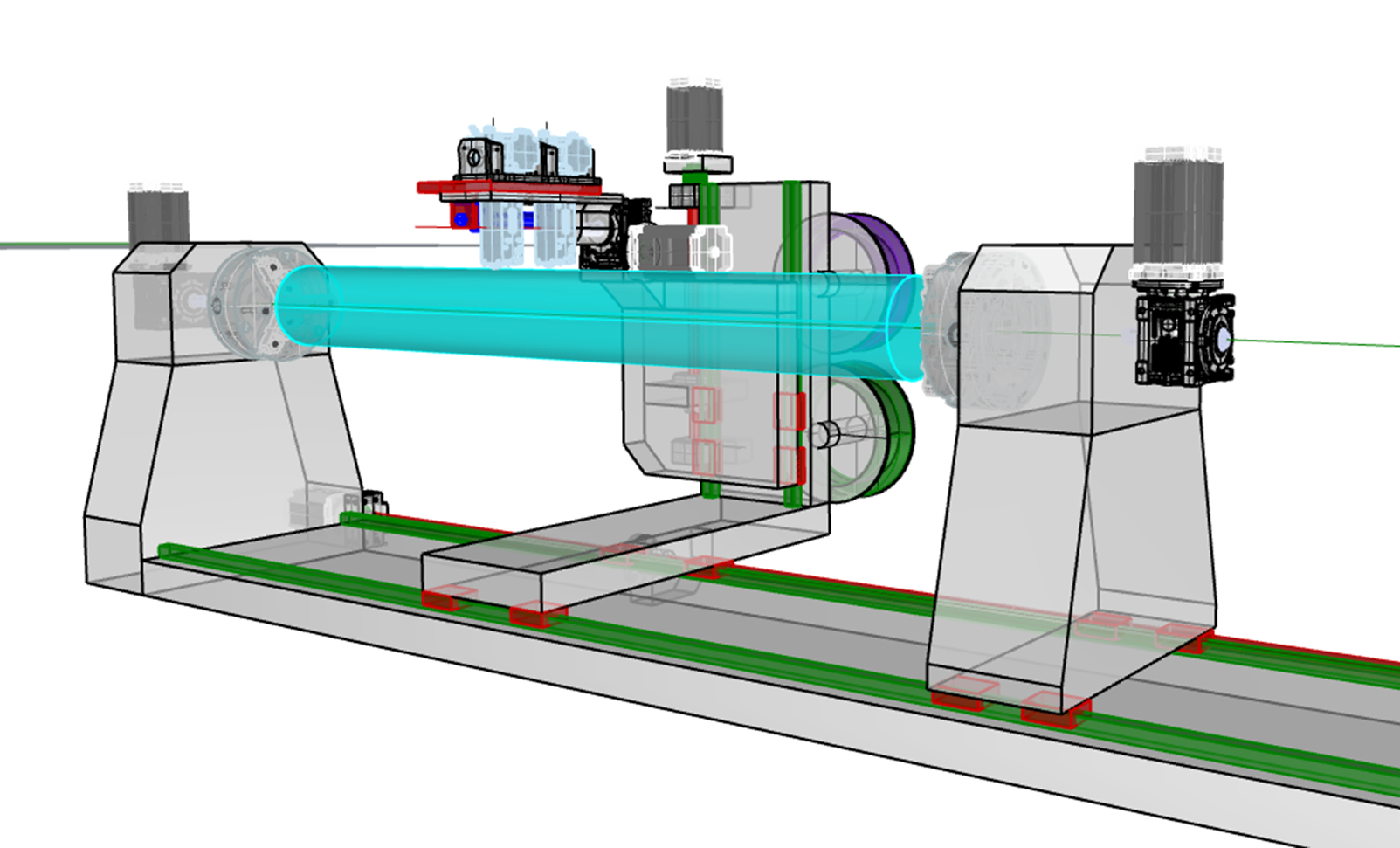

A versatile linear axis rotary 3D printer capable of handling both small and large items. With precision and speed, it’s a perfect tool for complex geometries in both terrestrial and space environments.

Read More

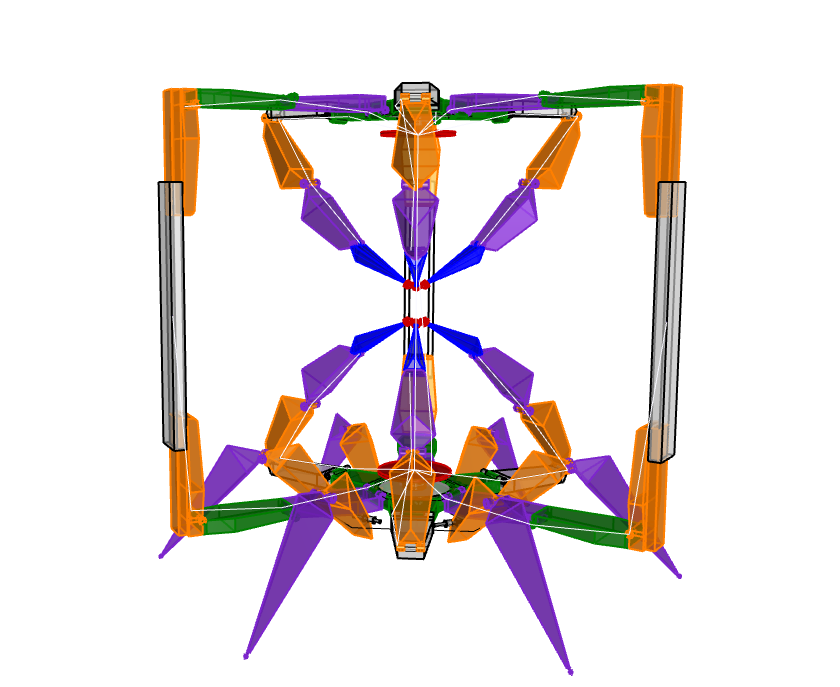

The Spider Rotary 3D Printer is an autonomous, spider-like 3D printer designed specifically for traversing rugged and remote terrains such as the moon, Mars, or challenging environments on Earth.

Read More

The Scorpion Robo-3D Printers are advanced, scorpion-like robotic units designed to collaborate as a coordinated team to build large, intricate structures in remote or challenging environments.

Read More

The Low Gravity Test Project is designed to simulate the unique challenges posed by operating in environments with reduced gravity, such as the moon, Mars, or deep space.

Read More

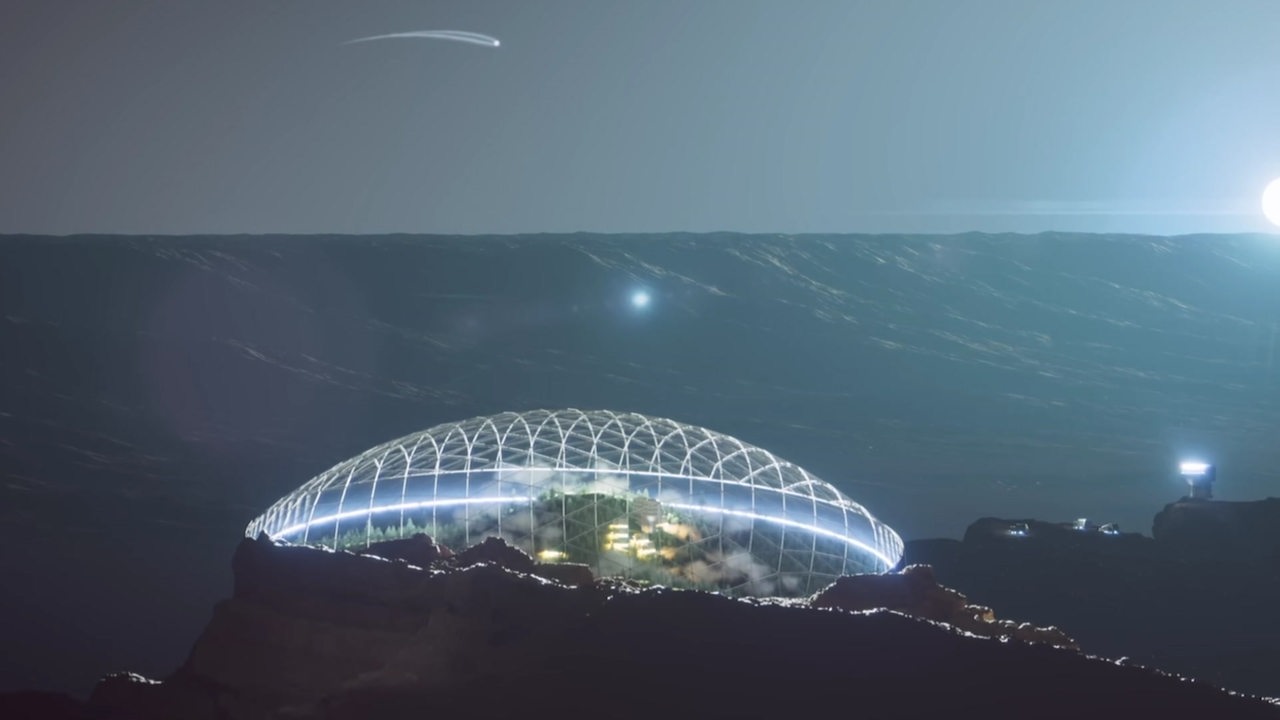

The Moon Launch Project is dedicated to advancing 3D printing technology to create sustainable habitats and infrastructure directly on the moon's surface.

Read More

The Orbit Habitat Constructor 3D represents a revolutionary approach to constructing and maintaining space stations and artificial habitats in orbit.

Read More

NebulaForm, founded by Prof. Dr. Dr.-Ing. Yilmaz Uygun and Serkan Özkan, is breaking new ground in space exploration by developing large-scale 3D printers for the aeronautics industry. With support from ESA BIC Northern Germany, they aim to revolutionize how components are manufactured in space.

Read More

Prof. Yilmaz Uygun and his team at Constructor University are pushing the boundaries of space exploration with NebulaForm, developing the world’s largest industrial 3D printer to create parts in space. Their innovative, zero-gravity printer could one day print entire habitats on the Moon or Mars.

Read More

A research team at Constructor University in Bremen is pioneering the tools for building homes on the Moon and Mars using 3D printing technology. Featured on buten un binnen, the team has developed two innovative 3D printers designed for space construction.

Read More

NebulaForm, a startup founded by Prof. Yilmaz Uygun from Constructor University, has been accepted into ESA’s space incubator. The team is developing the world’s largest Delta-3D printer for manufacturing aerospace components and is working on a space-ready 3D printer for zero-gravity conditions.

Read More

Prof. Yilmaz Uygun and his team at Constructor University are revolutionizing space manufacturing with 3D printing. Their startup, NebulaForm, has joined ESA’s incubator program, aiming to develop groundbreaking solutions for space industries.

Read More

NebulaForm, founded by Prof. Yilmaz Uygun from Constructor University, is developing the world’s largest Delta-3D printer to produce unique components for space missions. Their work is supported by the ESA BIC Northern Germany space incubator, fostering cutting-edge innovations in aerospace manufacturing.

Read More

NebulaForm, a startup led by Prof. Yilmaz Uygun, is leveraging the world’s largest Delta-3D printer to create custom parts for the aerospace industry. Their innovations have attracted the attention of ESA, leading to the startup being accepted into the prestigious ESA BIC Northern Germany incubator.

Read More

The world’s largest industrial Delta-3D printer, developed in Bremen, is revolutionizing the production of large-scale components. Featured on "Forschung Aktuell" by Deutschlandradio, this innovative technology is reshaping how industries like aerospace and prototyping approach manufacturing.

Read More

Prof. Yilmaz Uygun and his team at Constructor University have developed the world’s largest industrial Delta-3D printer, dubbed "Honeycomb." This groundbreaking machine is set to transform industries like prototyping, offering faster, more flexible, and cost-efficient solutions.

Read More

In October 2019, Yilmaz and Serkan made a pivotal decision to develop a large industrial-grade 3D printer for constructing their unique vertical axis wind turbine...

Read More

In August 2018, Serkan Özkan, Co-founder of NebulaForm GmbH, embarked on his journey at Jacobs University to focus on renewable energy research under the guidance of Prof. Dr. Dr. Yilmaz Uygun...

Read MoreNebulaForm GmbH

An Rauchs Gut 24

28759 Bremen, Germany

VAT Number (Umsatzsteuer-Identifikationsnummer): DE369127770

Tax Number (Steuernummer): 60 124 00975

Commercial Register (Handelsregister-Nr.): HRB 40239 HB

EBID Number: 2 500697 313653

Managing Director:

Serkan Özkan

Bank Details:

IBAN: DE11 2905 0101 0084 0742 02

Contact Information:

Email: info@nebulaform.com

Ready to learn more about how NebulaForm is transforming space exploration? Get in touch with us today!

Co-Founder

Research Associate at Constructor University

Co-Founder

Professor at Constructor University, Bremen

Operations Manager

Mathematics BSc. student at Constructor University

Mechatronic Engineer

Robotics and Intelligent Systems BSc. student at Constructor University

Mechatronic Engineer

Computer Science BSc. student at Constructor University

Team Assistant

Industrial Engineering and Management BSc.